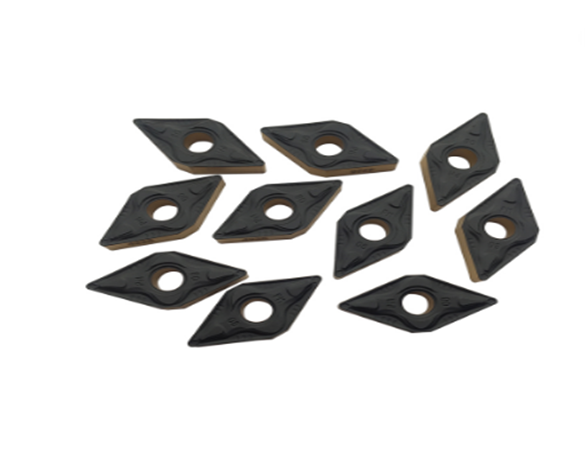

Tungsten carbide cutting blade

Hits:

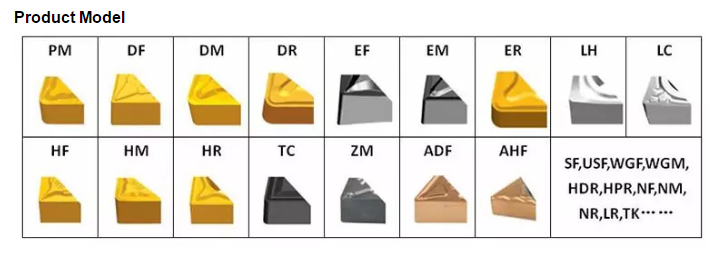

Basical Information: No Chip Breaker Introduction 1 PM Double sided chip breaker for medium machining. Wide range of application in steel and cast iron. 2 DF Double sided chip breaker with good chip control. Suitable for finishing and medium machining of steel and cast iron. 3 DM Double sided chip breaker for medium machining. Wide range of application due to excellent balance of sharpness and cutting edge stability. 4 DR Double sided chip breaker with positive rake angle and stable cutting edge for light to medium roughing of steel and cast iron. 5 EF Double sided chip breaker with good chip control. Suitable for finishing and medium machining of steel and cast iron. 6 EM Double sided chip breaker with sharp cutting edge and large rake angle. Process reliable medium machining of stainless steel. 7 ER Double sided chip breaker with large rake angle for low cutting forces. Suitable for roughing of stainless steel. 8 LH Single sided chipbreaker for machining of cast aluminium alloys. Sharp cutting edge with positive rake angle. G-tolerance for high repeatability. 9 LC Single sided chip breaker with excellent cutting edge design. Sharp cutting edge with positive rake angle. G-tolerance for 10 HF Single sided chip breaker with good chip control. Suitable for finishing to medium machining of steel and cast iron. 11 HM Single sided chip breaker for medium machining. Wide range of application due to excellent balance of sharpness and cutting edge stability. 12 HR Single sided chip breaker with positive rake angle and stable cutting edge for light to medium roughing of steel and cast iron. 13 TC Double sided chip breaker with surrounding cutting edge. Process reliable machining due to highest cutting edge stability. MORE DETAILS,PLS CONTACT US .

Place of Origin: Guizhou, China (mainland)

Brand Name: Zhongbo

Product Name: Tungsten carbide cutting blade

Type: Cutting tool

HRA: 85-93

Application: Indusitry

Mould Number: Customized

Certification: ISO9001

Surface: Grinding and polishing to mirrior

Product Description:

ISO

GradeHardness

(HRA)¡À0.5 Density

(g/cm3)¡À0.3 TRS

(MPa)minCharacteristics and Application

K05

92.3

14.55-14.7

2500

Sub-micron grain, apply to cutting composite material, finish machining of non-ferrous matals

and woodworking tools.

K20-K30

91.8

14.35-14.50

3000

Sub-micron grain, apply to cutting corrugated board, chemical fiber, plastics, leather, battery pole

pieces, all kinds of milling cutters and hole machining tools.

K40

90.5

13.95-14.1

3200

Sub-micron grain, superb abrasive resistance and toughness, apply to woodworking cutters, cutting

corrugated board, battery pole pieces etc.

K40

89.8

13.80-13.95

3200

Sub-micron grain, superb abrasive resistance and toughness, apply to woodworking cutters, rolling

shear blades, suitable for cutting paperboard.

Characteristic:This kind of blade is made by best pure tungsten carbide raw material, guaranteed high hardness and high wear resistance, the cutting

edge is very sharp,flatness and high precision degree.Have long service life.